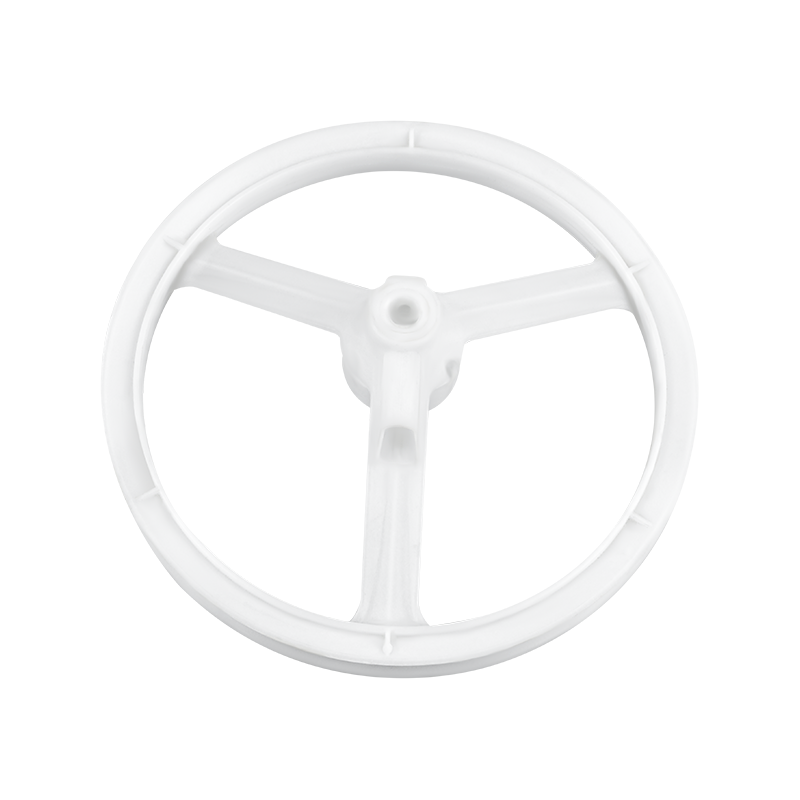

The washing machine speed reducer is one of the core components inside the washing machine. It is responsible for reducing the speed of the motor and increasing the torque, thereby driving the mixing barrel to rotate to complete the washing task. However, due to long-term use or other reasons, the reducer may malfunction or be damaged, affecting the normal operation of the washing machine. Therefore, it is crucial to promptly determine whether the reducer needs to be replaced or repaired. Here are some common ways to tell if a reducer needs repair or replacement:

1. Abnormal sounds: If you hear unusual creaking, clicking or other unusual sounds when the washing machine is working, it may be a problem with the reducer. Normally, a properly working reducer should run smoothly without excessive noise. Therefore, unusual sounds could mean worn gears, loose bearings, or other mechanical component failures.

2. Oil leakage or insufficient lubrication: Washing machine speed reducers usually require certain lubricants to reduce friction and wear. If you notice signs of oil or grease leaking from your reducer, or if the lubricant is depleted, it will most likely need repair or replacement. Oil leakage may cause increased gear wear, thereby affecting the normal operation of the reducer.

3. The speed is unstable or too low: If the speed of the washing machine is unstable or drops significantly during operation, there may be a problem with the reducer. Failure of the reducer will cause insufficient motor output, thus affecting the normal rotation of the mixing barrel. Checking whether the speed of the reducer is consistent with the specifications during normal operation can help determine whether the reducer needs repair or replacement.

4. The mixing barrel cannot rotate or is difficult to rotate: If you find that the mixing barrel of the washing machine cannot rotate normally, or it is very difficult to rotate, the reducer may be faulty. Failure of the reducer may cause gear damage or bearing damage, thereby affecting the rotation of the mixing barrel. In this case, timely repair or replacement is required.

5. Strange or burning smell: If you smell burning or other abnormal smell when the washing machine is working, it may be that the reducer is malfunctioning. A burning smell may be caused by overheating or friction in the motor, which is often related to problems with the reducer. Inspecting the exterior and interior of the reducer for scorch marks can help determine whether the reducer needs repair or replacement.

6. Gear wear or damage: If the gear is found to be obviously worn or damaged when inspecting the reducer, it will most likely need to be repaired or replaced. Damage to the gear will affect the transmission efficiency and stability of the reducer, thereby affecting the working effect of the washing machine.

7. System fault code: Some modern washing machines are equipped with a fault self-diagnosis function. You can use the system fault code to determine whether the reducer needs to be repaired or replaced. If your washing machine displays a fault code related to the reducer, it will most likely require inspection and repair.

中文简体

中文简体

عربى

عربى

.png?imageView2/2/format/jp2)

.png?imageView2/2/format/jp2)

.png?imageView2/2/format/jp2)

.png?imageView2/2/format/jp2)

.png?imageView2/2/format/jp2)

.png?imageView2/2/format/jp2)

.png?imageView2/2/format/jp2)

.png?imageView2/2/format/jp2)

.png?imageView2/2/format/jp2)

.png?imageView2/2/format/jp2)